Floating Fish Feed Pellet Line

Floating Fish Feed Pellet Line Processing

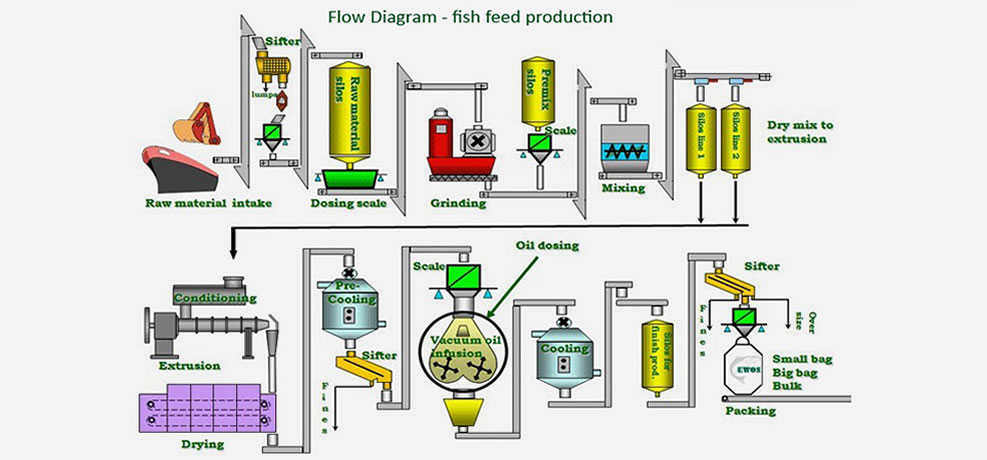

Material crushing→material mixing→extruding process→pellets drying→oil spraying process→pellets cooling→pellet packing

1.Crushing

Raw materials first are crushed by the fish feed crusher. The particle size directly effects the efficiency of pellet making. Once feeding into the crushing chamber, materials are smashed under the high-speed rotation of hammers. With the high pressure and rapid-moving of airflow, the smashed raw materials are further reduced into particle size or very small pieces for further processing. Therefore fish feed hammer mill is suitable for fish feed pellet grinding in the production line.

2.Fish Feed Mixer Machine

Powdery feed materials need to be mixed thoroughly in the mixer to ensure a high-quality of nutritional feed. We provide feed mixer with a single-shaft and twin-ribbon. It reinforces convection, shearing, and mixing effects and is an essential parts of the whole line.

3. Extruding

After mixing, feed pellet extruder will compress feed powder into sized pellets. Dry Type Fish Feed Extruder is the significant equipment with reliable performance, easy operation and cheap price, which is economic for small and medium scale production. Therefore dry type feed pellet making machine are recommend in the feed pellet plant.

4. Drying

Fish feed pellets from pellet making machine need to lower high moisture and temperature. So mesh belt dryershould be equipped in the production line. With simple structure, it is easy to install and maintain, and ideal for fish feed pellets drying.

5. Oil Spraying Process

For acquiring better smell and taste, the oil spraying machine can be used to spraying oil to the surface of fish feed pellets coming out of the dryer. It sprays atomized oil with high speed on the up and down surface of pellets, and the excessive oil can be recycled through filter.

6. Pellet Cooling

Hot pellets are soft and easily broken, which can result in a high percentage of fines. By cooling pellets can be harden.Counter flow cooler is cooling type that commonly used in pellet industry currently with the direction of the air and product of pellets in opposing directions.

7. Fish Feed Pellet packaging

The fish feed pellets are packaged in bags for further transporting and storage. Here you can opt pellet packing machinewhich is suitable for weighing and bagging pellets. Using packaging machine can increase productivity, reduce labor intensity and satisfy the needs of large-scale production and meet hygiene requirements.

Material crushing→material mixing→extruding process→pellets drying→oil spraying process→pellets cooling→pellet packing

1.Crushing

Raw materials first are crushed by the fish feed crusher. The particle size directly effects the efficiency of pellet making. Once feeding into the crushing chamber, materials are smashed under the high-speed rotation of hammers. With the high pressure and rapid-moving of airflow, the smashed raw materials are further reduced into particle size or very small pieces for further processing. Therefore fish feed hammer mill is suitable for fish feed pellet grinding in the production line.

2.Fish Feed Mixer Machine

Powdery feed materials need to be mixed thoroughly in the mixer to ensure a high-quality of nutritional feed. We provide feed mixer with a single-shaft and twin-ribbon. It reinforces convection, shearing, and mixing effects and is an essential parts of the whole line.

3. Extruding

After mixing, feed pellet extruder will compress feed powder into sized pellets. Dry Type Fish Feed Extruder is the significant equipment with reliable performance, easy operation and cheap price, which is economic for small and medium scale production. Therefore dry type feed pellet making machine are recommend in the feed pellet plant.

4. Drying

Fish feed pellets from pellet making machine need to lower high moisture and temperature. So mesh belt dryershould be equipped in the production line. With simple structure, it is easy to install and maintain, and ideal for fish feed pellets drying.

5. Oil Spraying Process

For acquiring better smell and taste, the oil spraying machine can be used to spraying oil to the surface of fish feed pellets coming out of the dryer. It sprays atomized oil with high speed on the up and down surface of pellets, and the excessive oil can be recycled through filter.

6. Pellet Cooling

Hot pellets are soft and easily broken, which can result in a high percentage of fines. By cooling pellets can be harden.Counter flow cooler is cooling type that commonly used in pellet industry currently with the direction of the air and product of pellets in opposing directions.

7. Fish Feed Pellet packaging

The fish feed pellets are packaged in bags for further transporting and storage. Here you can opt pellet packing machinewhich is suitable for weighing and bagging pellets. Using packaging machine can increase productivity, reduce labor intensity and satisfy the needs of large-scale production and meet hygiene requirements.

Send your message to us:

-

Floating Fish Feed Pellet Line

-

Floating Fish Feed Pellet Line

-

Floating Fish Feed Pellet Line

-

Floating Fish Feed Pellet Line

-

Floating Fish Feed Pellet Line

-

Floating Fish Feed Pellet Line

-

Floating Fish Feed Pellet Line

-

Floating Fish Feed Pellet Line

-

Floating Fish Feed Pellet Line

-

Floating Fish Feed Pellet Line