Simple single-axis spiral ribbon mixer

2. The procedure of adding material into premix feed: the grease should be account for 1% - 3% of the total proportion of the material, this can improve the taste and appearance of the feed, also can reduce the dust.

single-axis spiral ribbon mixer

3. Guarantee the mix time of the mixer, the normal material should be mixed for about 5 minutes to make sure the material was well mixed.

Single-shaft paddle mixer

4. Prevent the leakage of the discharging door: check if the installation position of the travel switch is correct and the contact between the material door and the casing is good. If the contact between the material door and the casing is not strict, the nut on the discharge door can be adjusted so that the discharge door and the bottom arc surface of the casing are level; if the gasket is aging, it should be replaced in time.

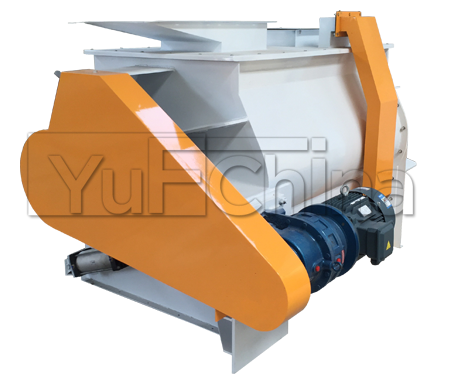

Double-shaft paddle mixer

5. Premix processing equipment should be cleaned: the mixer, silo and conveyor should be cleaned if the formula of the premix feed is changed. The clean method is add the materials and operate twice, normally the washed feed can not be recycled. If want to recycle, can add 0.5% of the dosage to the mixer to mix with fresh materials.If there are some grease adhered in the mixer, it should be cleaned manually.

YuFChina can provide you with different purchase guidance of the Biomass pellet equipment, we can customized your own pellet production line according to your requirements. We have many years experience in exporting the biomass pellet production equipment, we have completed after-sales service, our engineers are available to offer installation guidance in your site, give you a whole service scheme.