Supply Fish feed pellet making line

We are fish feed pellet plant manufacturer that help small, medium and large-scale fish pellet plant clients to set-up a fish pellet plant.

We will design the plant to meet your specific demands at different capacities. We offer all kinds of fish feed pellet machines including floating fish feed pellet machine and sinking feed pellet machine.

Fish Pellet Machine Application

Our fish pellet production line is perfect with the raw material of grains, grass, protein and molasses for commercial purposes.

The end product feed pellets have fine textures, are nutrient-rich, have a unique taste, and are of various shapes. They are perfect for aquatic animals like shrimps, gold-fish, cat-fish, tropical fish etc.

If you own a breeding farm, and you have medium or big-size feed mills, our line of fish feed pellet machine is your best choice because they use super automation controls and are highly efficient. Please feel free to contact us if you have any questions about floating fish feed pellet making or interested in getting more details of your fish feed pellet machines!

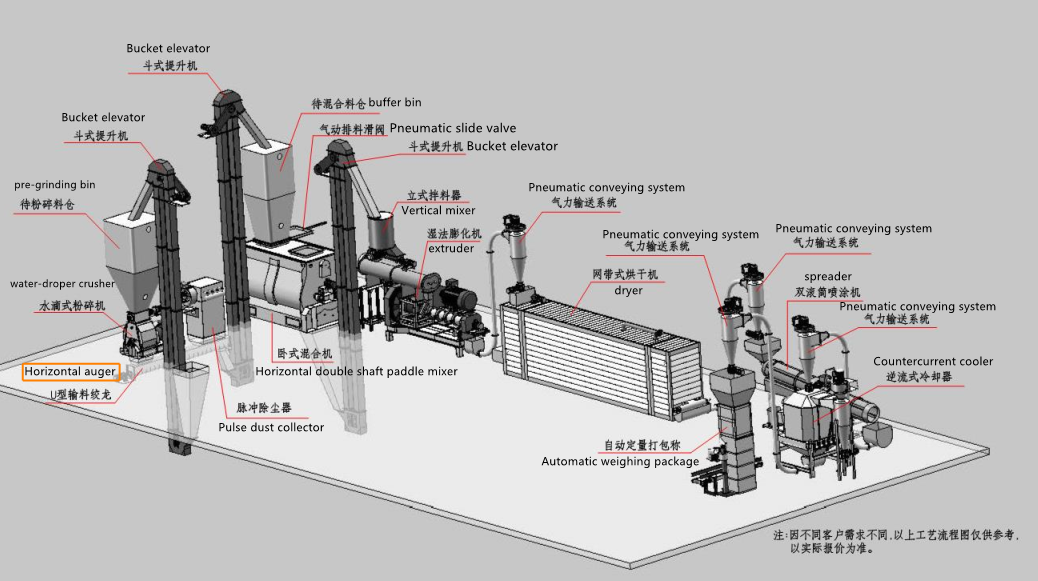

Fish Feed Pellet Production Line

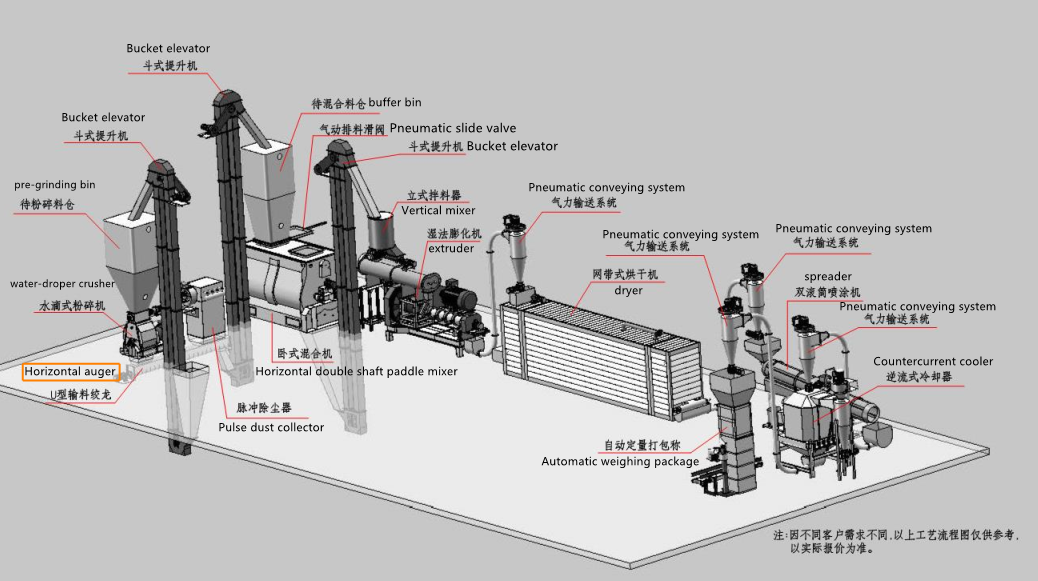

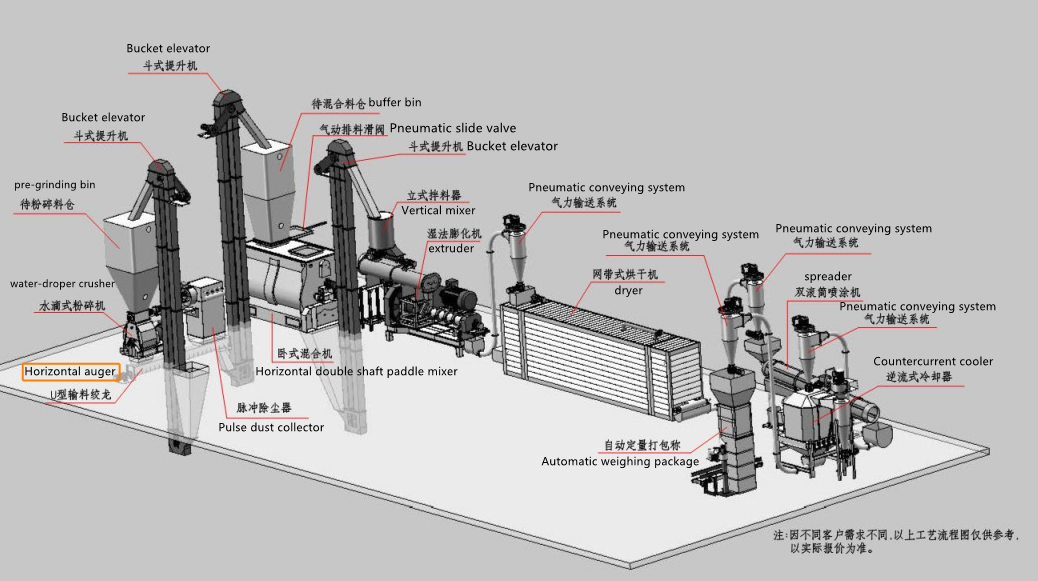

A complete pet food or fish feed pellet production line generally includes the following process:

raw material crushing—>raw material mixing—>pelle extruding process—>pellets drying—>oil spraying process—>pellets cooling—>pellet packing

Crushing

First we break the raw materials into smaller pieces by the hammer crusher for an efficient pellet making. This is done by high-speed rotating hammers within the crushing chamber. To further reduce the size, the materials are run through a rapid airflow of very high pressure, breaking the materials into much smaller pieces. A fish hammer mill is therefore necessary for raw material grinding in a fish pellet plant.

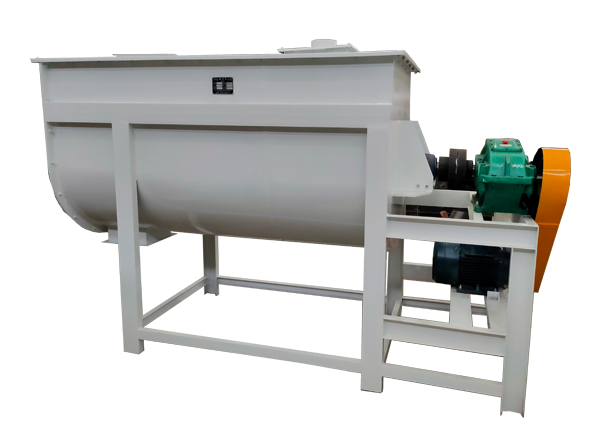

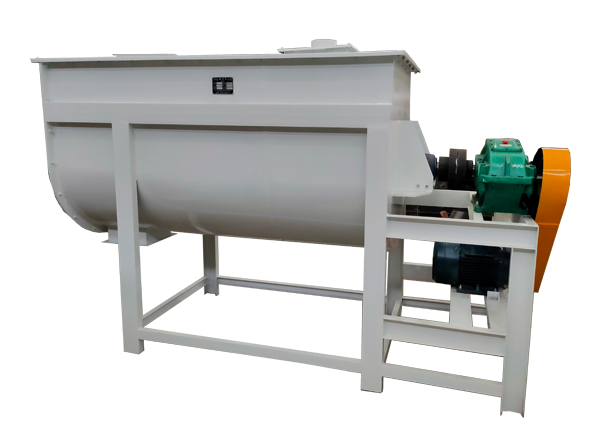

Mixing

Mixing the crushed materials which are in powdered form should be thoroughly mixed to get a fish feed that is nutritional and of high quality. We supply screw type and shaft type mixer for single and twin mode.

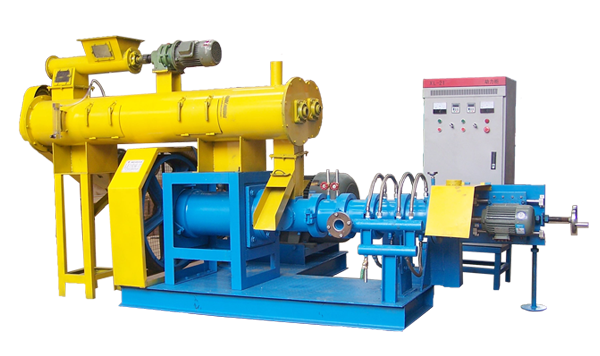

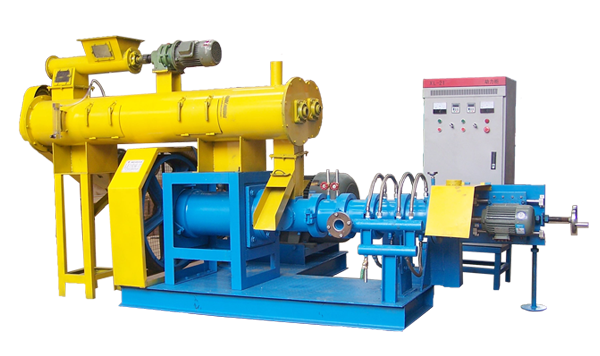

Extruding (fish feed pelletizing)

The mixed materials are compressed into desired shapes and pellet sizes with the fish feed pellet machine.

The dry type fish feed extruder is highly recommended for a small-scale or medium-scale fish pellet plant, as it is lower cost, easy-to-operate, and reliable for running.

For a large capacity with big factory and farm, we suggest the wet type feed extruder for a scale producton and high quality products.

Drying

In the wet solution fish feed extruder plant, drying machine is necessary through the complete production line. As the boiler steam and conditioner will increase the moisture of extruded pellet, to keep good shape, test and storage, we have to reduce the moisture by a dryer. The Mesh Belt Dryer is reputed and recommend for its good performance, simple structure and smoothly operating.

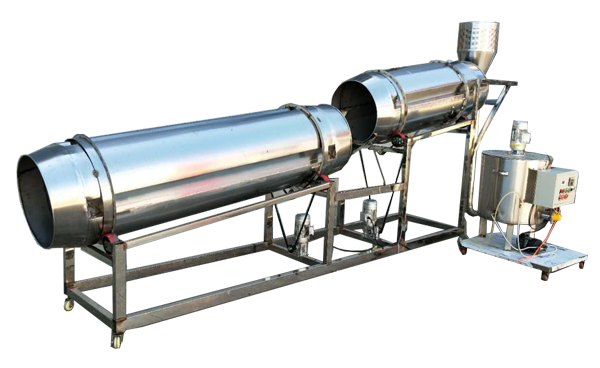

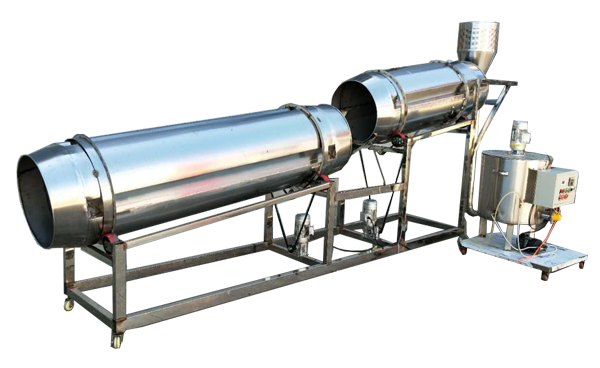

Oil Spraying

The good taste, nice smell and nutrients of the feed pellet is owed to the Oil Spraying Machine. This equipment rotates with high speed, spraying atomized oil on each surfaces of the fish feed pellets. Excess oil during this process is then recycled through a special filter.

Pellets Cooling

A cooler to keep good quality of fish feed pellet, its function are for reduce the moisture as well as temperature of the oil-sprayed pellets. Most of the clients adopt the counter flow cooler for the cooling section. In this fish feed cooler, feed pellet and cold air enters in opposite directions to form counte flow cooling system.

Pellets Packaging

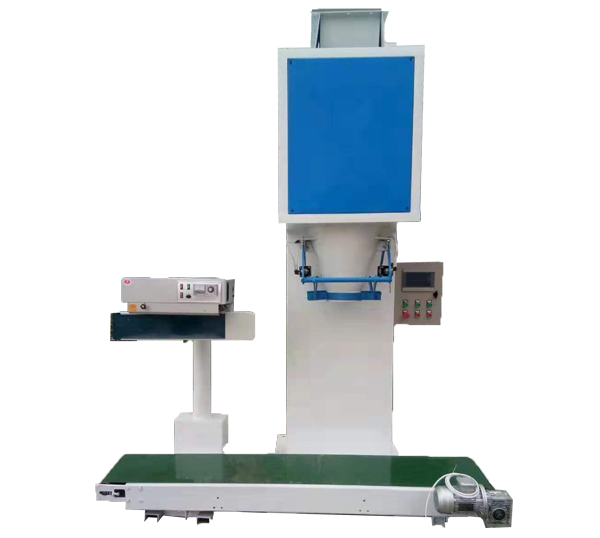

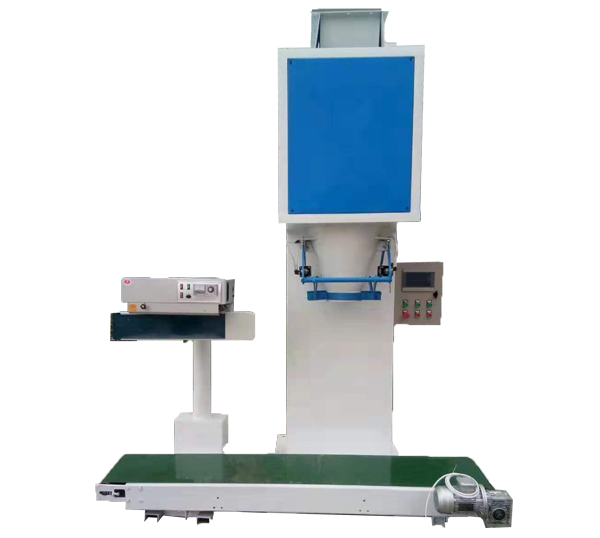

Packaing machine can help you in the bulk production of fish feed pellets, reduce labor intensity, keep high quality product, longer storage and meet hygiene requirement.

The packing machine include with scale device, sealing and packing.

Tons bag and KG bag are optional to choose.

Our fish feed pelletizing solutions are so flexible and allows you to customize your output configuration according to different feed types. If you are intending or will be starting your feed pellet making business soon be it in small-scale, medium or large scale, please contact us for more details as we are ready to help you with the best pelletizing solutions and give you a great after-service!

We will design the plant to meet your specific demands at different capacities. We offer all kinds of fish feed pellet machines including floating fish feed pellet machine and sinking feed pellet machine.

Fish Pellet Machine Application

Our fish pellet production line is perfect with the raw material of grains, grass, protein and molasses for commercial purposes.

The end product feed pellets have fine textures, are nutrient-rich, have a unique taste, and are of various shapes. They are perfect for aquatic animals like shrimps, gold-fish, cat-fish, tropical fish etc.

If you own a breeding farm, and you have medium or big-size feed mills, our line of fish feed pellet machine is your best choice because they use super automation controls and are highly efficient. Please feel free to contact us if you have any questions about floating fish feed pellet making or interested in getting more details of your fish feed pellet machines!

Fish Feed Pellet Production Line

A complete pet food or fish feed pellet production line generally includes the following process:

raw material crushing—>raw material mixing—>pelle extruding process—>pellets drying—>oil spraying process—>pellets cooling—>pellet packing

Crushing

First we break the raw materials into smaller pieces by the hammer crusher for an efficient pellet making. This is done by high-speed rotating hammers within the crushing chamber. To further reduce the size, the materials are run through a rapid airflow of very high pressure, breaking the materials into much smaller pieces. A fish hammer mill is therefore necessary for raw material grinding in a fish pellet plant.

Mixing

Mixing the crushed materials which are in powdered form should be thoroughly mixed to get a fish feed that is nutritional and of high quality. We supply screw type and shaft type mixer for single and twin mode.

Extruding (fish feed pelletizing)

The mixed materials are compressed into desired shapes and pellet sizes with the fish feed pellet machine.

The dry type fish feed extruder is highly recommended for a small-scale or medium-scale fish pellet plant, as it is lower cost, easy-to-operate, and reliable for running.

For a large capacity with big factory and farm, we suggest the wet type feed extruder for a scale producton and high quality products.

Drying

In the wet solution fish feed extruder plant, drying machine is necessary through the complete production line. As the boiler steam and conditioner will increase the moisture of extruded pellet, to keep good shape, test and storage, we have to reduce the moisture by a dryer. The Mesh Belt Dryer is reputed and recommend for its good performance, simple structure and smoothly operating.

Oil Spraying

The good taste, nice smell and nutrients of the feed pellet is owed to the Oil Spraying Machine. This equipment rotates with high speed, spraying atomized oil on each surfaces of the fish feed pellets. Excess oil during this process is then recycled through a special filter.

Pellets Cooling

A cooler to keep good quality of fish feed pellet, its function are for reduce the moisture as well as temperature of the oil-sprayed pellets. Most of the clients adopt the counter flow cooler for the cooling section. In this fish feed cooler, feed pellet and cold air enters in opposite directions to form counte flow cooling system.

Pellets Packaging

Packaing machine can help you in the bulk production of fish feed pellets, reduce labor intensity, keep high quality product, longer storage and meet hygiene requirement.

The packing machine include with scale device, sealing and packing.

Tons bag and KG bag are optional to choose.

Our fish feed pelletizing solutions are so flexible and allows you to customize your output configuration according to different feed types. If you are intending or will be starting your feed pellet making business soon be it in small-scale, medium or large scale, please contact us for more details as we are ready to help you with the best pelletizing solutions and give you a great after-service!

Send your message to us:

-

Supply Fish feed pellet making line

-

Supply Fish feed pellet making line

-

Supply Fish feed pellet making line

-

Supply Fish feed pellet making line

-

Supply Fish feed pellet making line

-

Supply Fish feed pellet making line

-

Supply Fish feed pellet making line

-

Supply Fish feed pellet making line

-

Supply Fish feed pellet making line

-

Supply Fish feed pellet making line